O-High Speed HD/LD Film Blowing Machine

| Model |

55-1200 |

65-1400 |

|

| Width of the film |

600-1000mm |

800-1200mm |

|

| Thickness of the film |

HDPE:0.008-0.08mm LDPE:0.02-0.15mm |

||

| output |

30-120kg/h |

40-150kg/h |

|

| According to different width, thickness of film,die size and raw material characteristics to change | |||

| Raw material |

HDPE/MDPE/LDPE/LLDPE/CACO3/RECYCLING |

||

| Diameter of screw |

Φ55 |

Φ65 |

|

| L/D ratio of screw | 32:1 (With force feeding) | ||

| Gear box |

180# |

200# |

|

| Main motor |

22kw |

37kw |

|

| Die diameter |

φ100/250mm |

φ150/300mm |

|

Above parameters only for reference,could be customized according to customer needs,detailed data pls check actual object

Product Description

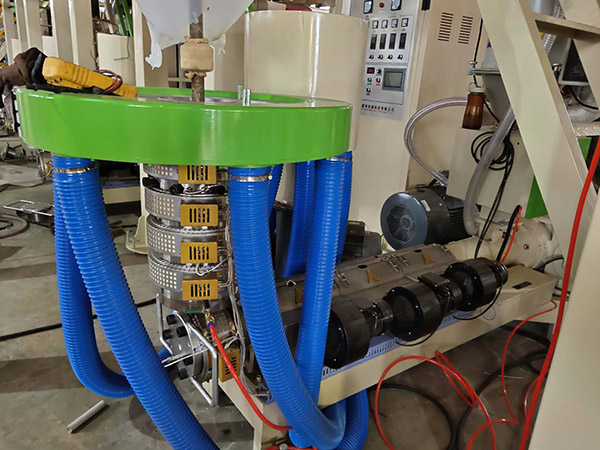

High speed HD/LD film blowing machine choose most suitable spares.Firstly, this machine adopts Siemens motor 100% authentic three-phase frequency conversion speed regulating motor, equipped with inverter control, international brand manufacturing which has higher accuracy and energy saving.Gear box adopting a dedicated hard tooth surface national standard reducer for extrusion machines, with a universal model and easily replaceable accessories.Adopting an internal and external oil circulation system.Oil pump with lubricates bearings to increase their service life.Gear box equipped with a cooling plate to reduce the heat generated during the operation of the gearbox, thereby achieving a cooling effect.Gear box with filter can filter lubricating oil magazine, ensuring the clarity of the oil.Second, the screw adopts customized dual alloy high-speed, high- plasticity screw, and the screw is equipped with water cooling device to maximize the machine output. The screw with 5 years warranty.And the screw L/D ratio is 32:1.Screw heating all adopt separate ceramic heating to guarantee each zone temperature. And separate ceramic heating with longer lifetime, If one zone damage, only change the one broken, no need changer all, save the production cost at a certain time.

Meantime,machine adopt Taiwan quality high-performance double duct wind ring/triple air duct wind ring and well-known brand wind ring of the same quality are used for cooling. Die head choose using 40Cr forging for precision machining and tempering treatment, long-term heating is not easy to deform. Finally,this machine winder adopts automatic discharge which adopts Siemens brand high-quality frequency conversion motor and is equipped with a gas rising shaft conveyor arm. The winding adopts the full tension control system, and the winding motor adopts servo motor control, which has high energy saving rate and ensures higher accuracy.

Optional device:

Automatic Hopper Loader

Film Surface Treater

Rotary Die

Oscillating Take Up Unit

Two Stations Surface Winder

Chiller

Heat Slitting Device

Gravimetric Dosing Unit

IBC(Internal Bubble Cooling Computer Control System)

EPC(Edge Position Control)

Electronic Tension Control

Manual mechanics screen changer

Edge material recycling machine

Related Products